Solutions

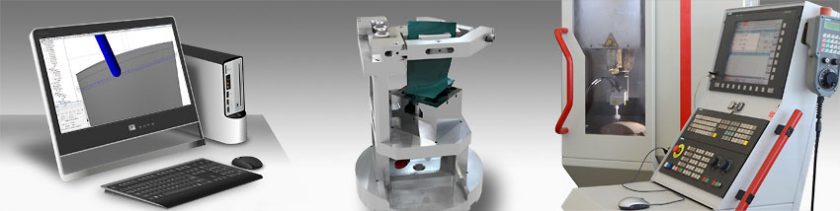

Our innovative software systems realise complex automation tasks in milling, grinding, cladding, coating, and additive manufacturing. For particularly demanding challenges, we integrate 3D scanners and process sensors into standard industrial machines and robots.

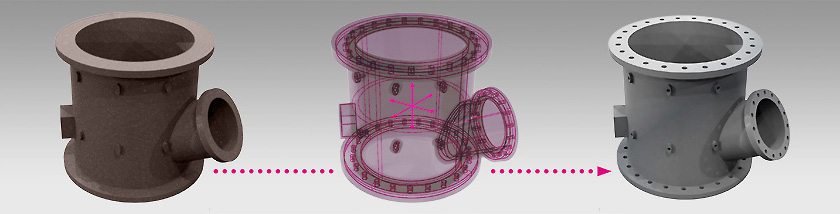

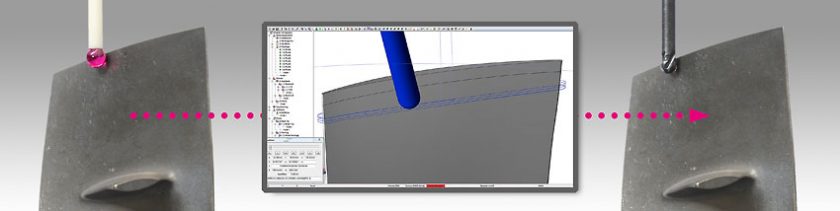

With our application modules, components can be automatically processed according to their individual shape or wear conditions. This allows our customers to repair, for example, engine or turbomachinery components and to customise components with AM. They also repair tools, deburr cast workpieces, machine AM components, and much more.

BCT solutions are modular and can therefore be combined to create automated processes and process chains.

- OpenSCAN: In-process laser line scanning and scan data preparation

- OpenFIT: Best-fit machining based on probe data and 3D scan data

- OpenDED: NC path generation for DED based on CAD and 3D scan data for additive and hybrid processes; automatic DED process for rotary components

- OpenDATA: In-process sensor data acquisition, spatially resolved display, and evaluation

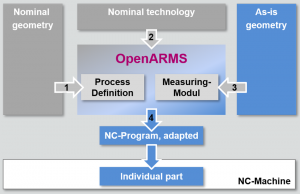

- OpenARMS (Open Adaptive Repair and Manufacturing Software): Application-specific automation solutions for adaptive machining

BCT solutions are open to industry-standard CAD and CAM formats, sensors, and controllers, and support both Cartesian machines and industrial robots. For the development of applications, we have several 3D printers, a 5-axis machining centre, a robot cell with an 8-axis robot available, as well as various 3D line scanners and process sensors.