CMC-3D

Development of an automatic inline measurement and defect detection system for efficient, adaptive finishing of complex CMC turbine components

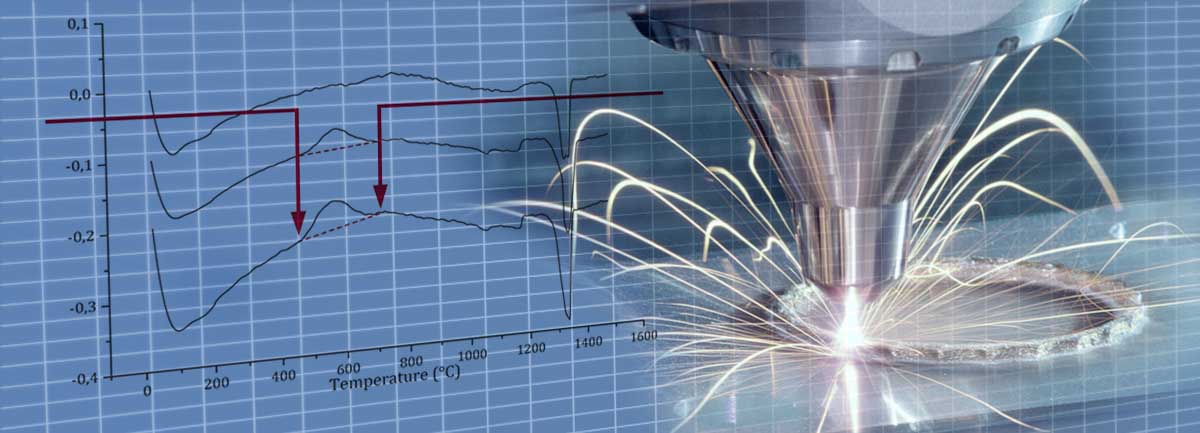

Increasing the efficiency of aircraft engines requires higher operating temperatures. Ceramic matrix composites (CMC) can withstand the high loads in the engine and thus allow higher operating temperatures than components made of nickel-based alloys.

The mechanical processing of CMC components presents new challenges for manufacturing technology. The workpieces themselves exhibit small defects such as pores and cracks that must be machined or addressed. In addition, microcracks in the surface and local spalling and delamination occur during the machining of oxide and non-oxide CMC materials.

In CMC-3D, the actual geometry of the CMC blank is captured using high-precision 3D scans with white light interferometry (WLI). Based on this data, NC machining can be flexibly and automatically adapted to the actual blank, taking into account any quality defects.

BCT integrates the WLI sensor into a 5-axis machining center and spatially assigns detected defects to the component’s geometry. Adaptation technology is used for optimal milling of CMC components, enabling customised machining tailored to the defects.